Several years ago, sunflower kernels were seen mainly as a simple snack or bakery ingredient. Today, the dehulled, edible kernels of sunflower seeds are one of the core raw material in the global food industry. Their applications reach far beyond snacking. They are used by bakeries, granola and bar manufacturers, seed-mix producers, protein powders, spreaded butters and brands developing plant-based and clean-label product lines.

As health awareness and plant-forward diets rise, sunflower kernels have become a symbol of a modern, versatile ingredient. It combines nutritional value with supply stability and wide-ranging functionality. For producers and import managers, they offer formulation flexibility and dependable sourcing regardless of shifting market trends.

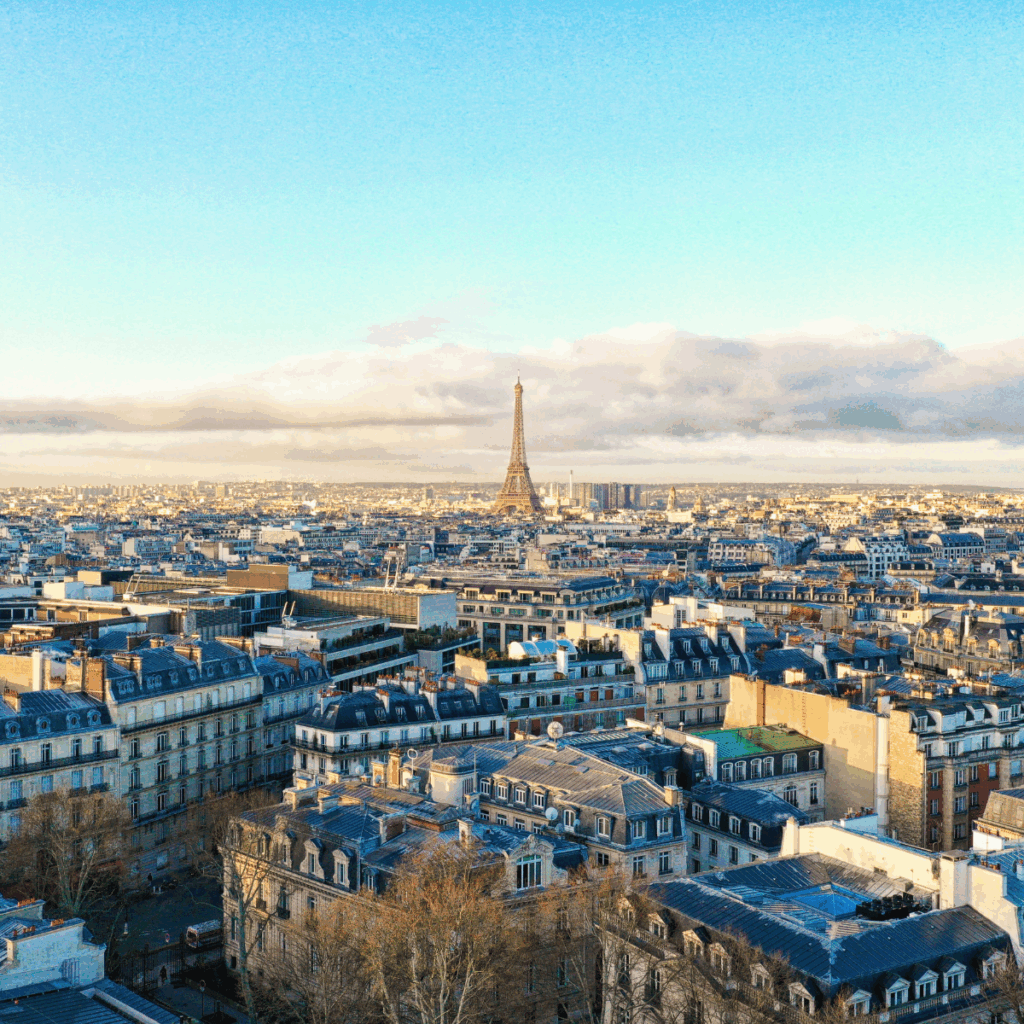

In Europe, the sunflower landscape has shifted notably in recent years. With trade patterns changing, Bulgaria and Moldova have assumed the role of key suppliers. This countries shaping European availability of bakery- and confectionary-grade sunflower kernels in particular.

This evergreen guide covers origin, processing, and applications of sunflower kernels – designed for importers, producers, and buyers seeking clarity in an evolving market.

What Are Sunflower Kernels?

Sunflower kernels are the dehulled, edible inner part of the sunflower seed (L. Helianthus annuus). The husk is removed through a mechanical process called dehulling, in which the hard outer shell is separated from the kernel.

After dehulling, the product is carefully cleaned and refined using a combination of pre-cleaners, destoners, screen separators, gravity tables, optical sorters, x-ray machines, and metal detectors to ensure purity and consistent quality for food processing.

Dehulled kernels are valued for their mild taste, natural color, and broad functionality across multiple food categories, from bakery to plant-based formulations.

Related article: Sunflower Market Update – August 2025

Sunflower Kernels Types

In global trade, sunflower kernel are classified into three main commercial types (grades), which differ in size, color, purity, and percentage of broken kernels. Each serves distinct industrial applications, from premium snacking to pet food blends.

- Sunflower Kernels: Bakery Grade – the standard and most popular grade on the market, widely searched among importers, bakeries, snack manufacturers, and packing companies. It is ideal for bakery, packing and industrial sector.

Bakery-grade kernels typically contain up to 7–8% broken seeds, which is acceptable in most food applications. Some producers also offer a Bakery Premium version, limiting broken kernels to 4–5%. These lots are usually better refined – often optically cleaned and X-ray sorted – providing higher visual quality and uniformity preferred in export-oriented production. - Sunflower Kernels: Chips (Hearts) – the smallest fraction of sunflower kernels, mainly used in the pet food industry, especially in bird mixes and animal feed.

- Sunflower Kernels: Confectionary Grade – larger, brighter, and longer kernels with lower oil content than bakery grade. They are preferred by confectionery producers and high-end snack brands that prioritize visual appeal, kernel size, and consistency.

Confectionery grade kernels are usually made from special sunflower varieties selected for size and color. Occasionally, you can also find Confectionery Premium lots, featuring fewer broken kernels and improved appearance for demanding export markets.

Takeaway: In today’s food industry, sunflower kernels are no longer a simple ingredient – they’ve become a strategic raw material driving innovation across multiple sectors, including bakery, packing, industrial food processing, plant-based, and protein applications.

Sunflower: Key Growing Regions

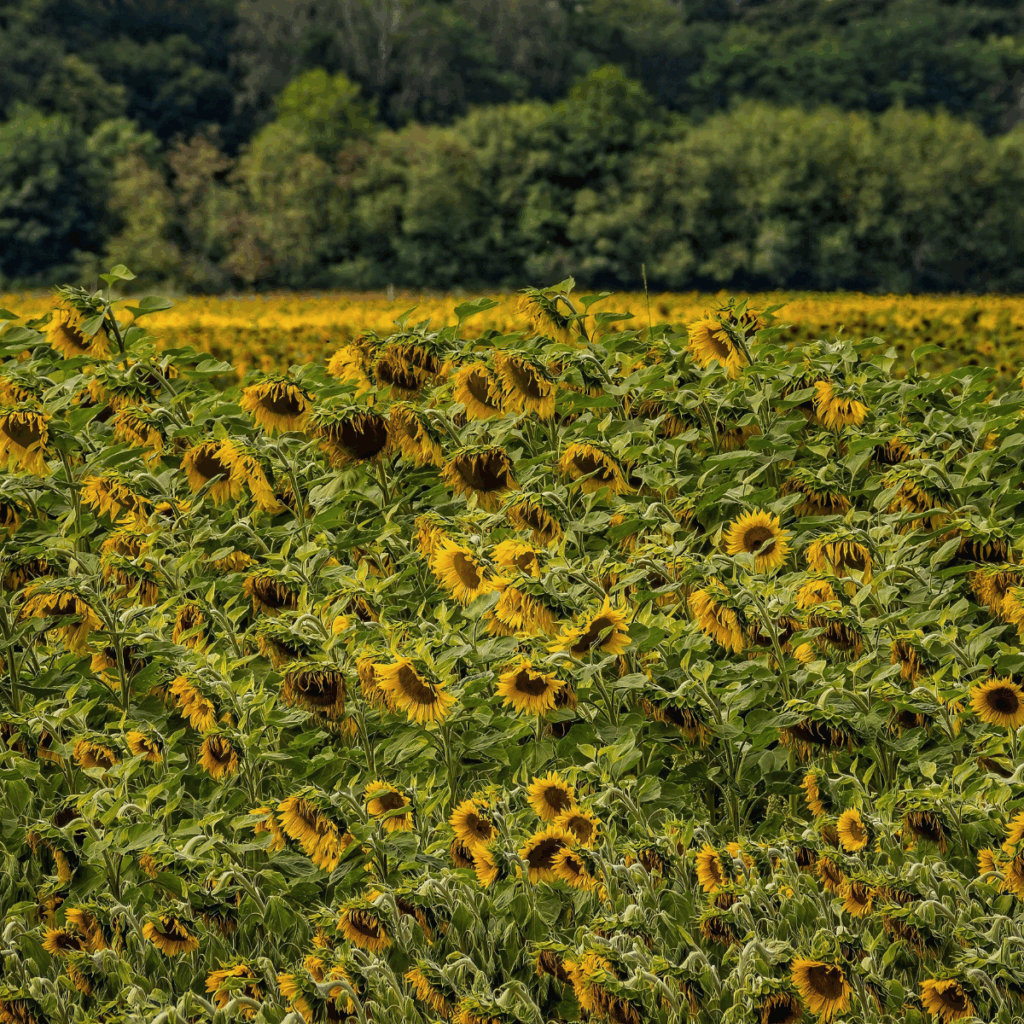

Most sunflower seed is cultivated for oil extraction, as the crop is naturally rich in oil and forms the backbone of global vegetable oil production. Only a small share – typically below ten percent of total volume – is used for kernel production. Sunflower seed is the third oilseed produced in the world, the fourth vegetable oil and third oilseed meal among protein feed sources. Global sunflower seed production for 2024/25 is estimated at around 54-55 million tons. The market is dominated by a few key producers:

- Russia – about 17 million tons (~32%)

- Ukraine – about 13 million tons (~25%)

- European Union – about 8.5 million tons (~16%)

- Argentina – about 5 million tons (~10%)

The Black Sea and Central European regions serve as the core of the global sunflower kernel trade, providing the majority of dehulled kernels for the food industry.

These markets – particularly Ukraine, Bulgaria, Romania, and Hungary – combine strong agricultural potential with advanced processing infrastructure.

Ukraine remains a leading origin for sunflower seeds destined for EU processing. Despite challenges, Ukrainian producers maintain consistent quality, especially in bakery-grade kernels used by hulling and packing plants across Europe.

Bulgaria and Romania continue to expand production, focusing on both linoleic (standard) and high-oleic (HO) hybrids. These countries have become key suppliers of kernel-ready sunflower, known for reliable quality and well-calibrated batches.

Takeaway: The global sunflower market is concentrated but efficient, with Europe – led by Ukraine, Bulgaria, Romania, and Hungary – defining the quality and availability standards for bakery and snack applications.

From Field to Final Product – The Processing Journey of Sunflower Kernels

Turning sunflower seeds into market-ready sunflower kernels is a multi-stage process in which every step influences the overall quality, purity, and sensory characteristics of the product. Though it may appear simple, it requires precise control, clean equipment, and modern technology to ensure consistent performance and food safety for end users.

Harvest

The process begins in early autumn (September – October), when sunflower heads reach full maturity and oil content peaks. Timely harvest is critical to minimize losses and prevent microbial growth.

Cleaning and Drying

Raw sunflower seeds are cleaned to remove plant residues, dust, and impurities. If necessary, the seeds are then dried to reduce moisture to 7–9%, preventing mold development and ensuring microbiological stability during storage and processing.

Dehulling

This stage involves the mechanical separation of the shell from the kernel. Dehulling must be carefully balanced: excessive force leads to broken kernels, while too mild separation leaves shell fragments in the final product.

Cleaning of Kernels

After dehulling, kernels undergo a multi-step cleaning process to remove shell fragments, dust, and light impurities. Depending on the plant design, this stage may include pre-cleaners, destoners, screen separators, gravity tables, optical sorters, x-ray machines, and metal detectors. Each system targets specific contaminants and ensures that the final kernels meet food-grade safety and purity standards.

Packing and Storage

Finished kernels are packed in paper bags, big bags, or vacuum-protected formats that guard against moisture and oxidation. When properly sealed and stored in cool, dry conditions, kernels retain freshness and stability for 12–18 months.

Safety Controls

To ensure compliance with EU and international food safety standards, finished kernels are systematically sampled and analysed for pesticide residues, heavy metals, and microbiological parameters. This step verifies that each batch meets the legal and customer-specific requirements for its destination markets. Only lots that comply with all safety limits are released for export.

A high-quality process directly shapes sensory attributes and nutrition. That’s why importers increasingly work with facilities investing in modern lines and maintaining international food safety standards (e.g., BRCGS, IFS, FSSC 22000).

Summary: Processing sunflower kernels combines agricultural expertise with precise engineering and strict quality control. Every stage, from harvest to final analysis, determines the purity, consistency, and reliability of the kernels supplied to the food industry.

Sign up to Seedea Newsletter

Join and get the Latest News & Product Reports from Seedea. It’s free. No spam.

Nutritional Profile and Health Benefits of Sunflower Kernels

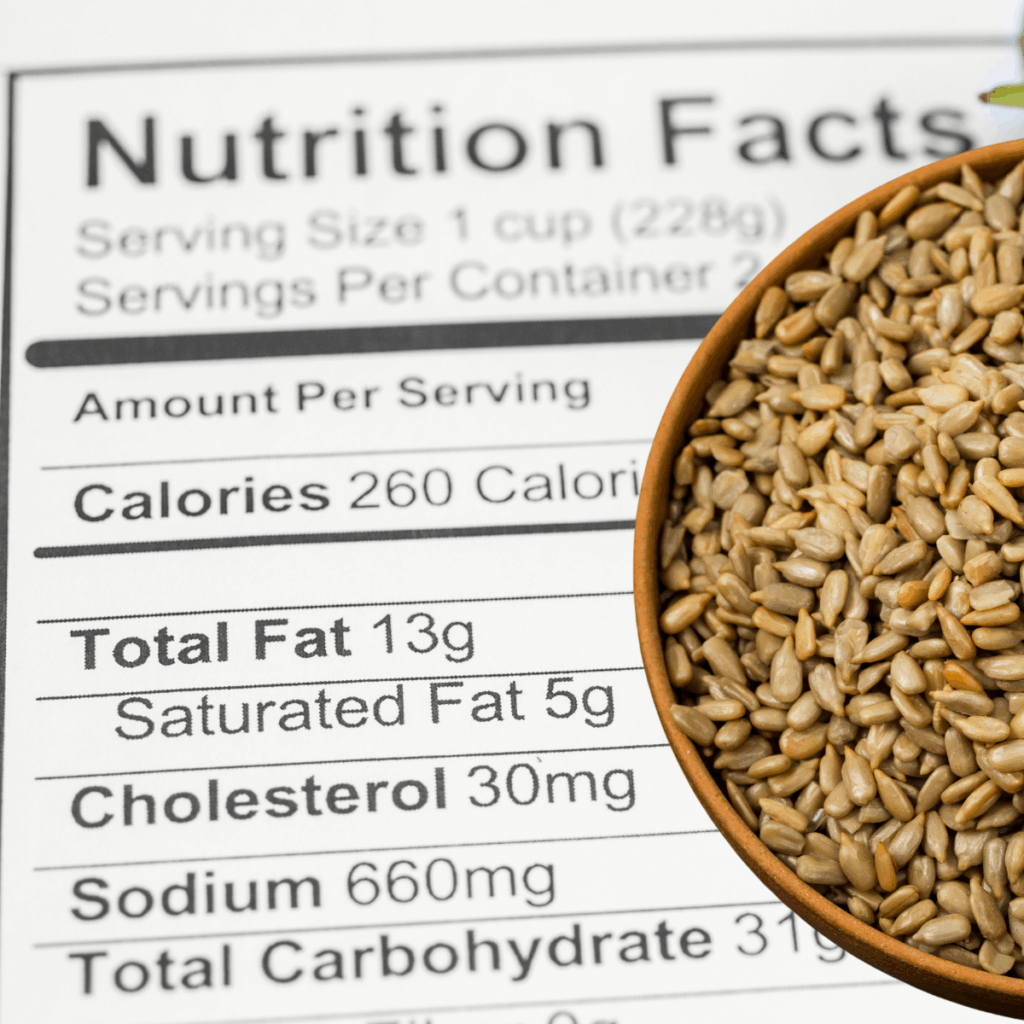

Sunflower kernels are a nutrient-dense plant ingredient-equally at home in functional, sports, and plant-based foods.

Per 100 g of kernels typically provides:

- About 20–22 g protein – a natural plant protein with a broad amino acid profile;

- ~50 g fats, predominantly unsaturated (omega-6 and omega-9), supporting cardiovascular health;

- Approximately 8–10 g fiber – aiding digestion and satiety;

- Notable vitamin E – a powerful antioxidant protecting cells from oxidative stress;

- Magnesium, zinc, iron, and selenium – essential minerals for immunity, metabolism, and cellular recovery.

This balance of protein, fats, and micronutrients makes kernels a mainstay in plant-based, sports nutrition, and functional snack formulations.

Compared to other seeds like sesame, flax, or pumpkin, sunflower kernels stand out for fat stability and a neutral flavor that adapts well across categories; from breads and granolas to spreads and dairy alternatives. Unlike many nut ingredients, sunflower kernels are naturally low-allergen, widening their consumer reach.

An additional advantage: sunflower protein is gaining traction as an alternative to soy isolates—thanks to a neutral taste profile and stable European supply with attractive lifecycle metrics.

Summary: with high protein, healthy fats, antioxidants, and key minerals, sunflower kernels align perfectly with global trends.

Common Uses of Sunflower Kernels in the Food Industry

The versatility of sunflower kernels makes them one of the most adaptable ingredients in modern manufacturing. Their gentle flavor, strong nutrition, and thermal stability allow them to replace nuts and other seeds across many formulas.

Bakery

Sunflower kernels are widely used in the bakery industry as part of multi-seed mixes and bread toppings. They add a pleasant nutty flavor, crunchy texture, and visual appeal to breads, rolls, crackers, and other baked goods. Their stable quality and cost efficiency make them a go-to ingredient for industrial bakeries across Europe.

Wholesale and Packing

A significant part of global sunflower kernel trade is handled by wholesalers and packing companies that buy bulk volumes for retail-ready packaging. These firms roast, calibrate, and pack kernels under private-label and own-brand formats for supermarkets, health food stores, and online retailers. The segment continues to grow in Europe in both retail and foodservice.

Industrial Use

Sunflower kernels are also used as a primary ingredient in further processing, including the production of sunflower protein, flours, and pastes for plant-based and functional foods. In addition, kernels are frequently incorporated into bakery mixes, granola clusters, and cereal bars, where they add texture, nutrition, and a clean-label profile to finished products.

Snacks

Confectionery kernels are roasted, salted, or seasoned, creating a wholesome alternative to chips and nuts. Their neutral taste supports broad flavor development; from classic salted and smoky notes to sweet-salty and herb-seasoned blends.

Ingredients and Spreads

Kernels are milled into flour and pastes or processed into sunflower protein for plant-based, sports, and vegan nutrition. They are also used to produce sunflower seed butter and spreads, a popular nut-free alternative to peanut or almond butter in both retail and industrial applications.

Summary: from multi-seed bakery mixes to snacks, plant-based spreads, and retail packaging, sunflower kernels combine flavor, functionality, and affordability making them one of the most versatile natural ingredients in modern food production.

Organic vs. Conventional Sunflower Kernels

The difference between organic and conventional kernels goes far beyond farming inputs. It reflects two distinct models of agriculture and supply.

- Conventional kernels come from intensive systems where mineral fertilizers and approved plant protection are used to maximize yields and ensure steady supply and competitive pricing. Typical yields reach 1.8–2.5 t/ha, making this the backbone of global trade and a pillar for oil pressing and large processors.

- Organic kernels are cultivated without synthetic fertilizers or pesticides, relying on rotation, biological protection, and natural fertilization. Yields are lower—often 1.0–1.5 t/ha—but market value is higher. In the EU and North America, demand for organic has grown consistently, driven by clean-label preferences and sustainability expectations.

Caution is crucial in organic systems: sunflower readily takes up substances from the soil, so legacy residues can compromise lab results and disqualify lots. As a result, organic fields may be established on new or long-rested land, often after a transition period.

Processing and QC also differ. Organic lots require additional certifications (e.g., EU Organic, USDA NOP) and routine audits with lab testing. This adds cost but strengthens brand trust in health food and vegan snacks segments.

Many European processors now diversify sourcing. Balancing conventional volumes for scale and stability with organic lots for premium markets and brand positioning.

Summary: conventional and organic kernels are complementary. Conventional ensures scale and predictability; organic addresses premium demand and clean-label positioning, strengthening brand equity.

Seasonality and Market Availability

Availability of sunflower kernels follows the crop cycle. While kernels are supplied year-round, volume, quality, and pricing reflect seasonal patterns.

- Harvest season in core European regions is September–October, when processors build stocks for the year ahead. Prices are typically lowest right after harvest due to abundant supply.

- As months pass and stocks draw down, prices tend to rise, especially in spring and summer. Weather in the following growing season (e.g., drought or heavy rain) and processing demand also shape the slope.

- Storage requires low humidity (<10%) and cool temperatures (<15°C). In proper conditions, kernels retain quality for 12–18 months. A major logistical advantage enabling stable, long-term contracts and production planning.

Despite sunflower’s relative drought tolerance, extended rainfall during maturation can reduce kernel quality, affecting dehulling performance and shelf life.

Summary: seasonal rhythms influence pricing and availability. Thanks to long shelf life and robust storage infrastructure, sunflower kernels remain reliably available year-round. For importers and manufacturers, this predictability translates into supply-chain security and optimized cost planning.

Related article: Sunflower Market Update – May 2024

Sustainability and Environmental Aspects

Although sunflower kernels evoke a natural, simple image, sunflower cultivation itself isn’t automatically “eco-friendly.” Sunflower is an agronomically important crop with clear environmental strengths and trade-offs that must be managed responsibly.

On the positive side, sunflower plays a valuable role in crop rotation. Its deep root system helps loosen soil, supports nutrient cycling, and can lower disease pressure. This is why it frequently rotates with wheat, maize, or rapeseed. Compared with some heavily irrigated crops, sunflower can tolerate periods of drought reasonably well. An advantage for parts of Central and Eastern Europe.

On the other hand, intensive sunflower systems, especially those supplying the oil industry can be demanding. Sunflower is a heavy feeder and can deplete soil nutrients quickly, which often necessitates mineral fertilization and crop protection. Sustainable practice therefore hinges on well-planned rotations. Inclusion of legumes to improve soil fertility, and careful nutrient management to avoid long-term degradation.

Processing is a relative strong suit: the sunflower chain is near zero-waste. Kernels go to food production. Hulls are repurposed for biomass or feed; oil and press cake flow into food and cosmetics. In recent years, many suppliers have also moved toward recyclable or recycled-content packaging, reducing plastics in the logistics chain.

Bottom line: sunflower has meaningful sustainability upsides and real constraints. Responsible soil stewardship, smart rotations, and full by-product utilization significantly mitigate its footprint without sacrificing production potential.

Takeaway: while sunflower kernels don’t come from an impact-free crop, the sector is steadily moving toward a balance between efficiency and responsibility. That’s why kernels now feature in the broader conversation about sustainable ingredients and the future of plant-based sourcing in Europe.

Why Sunflower Kernels Matter

Sunflower kernels aren’t just a convenient topping they’re a strategic ingredient that combines nutrition, supply predictability, and production flexibility. In a world leaning into plant-based and natural inputs, kernels hold a distinctive position in the food value chain.

Nutritionally, they deliver stable plant protein and healthy fats, fitting seamlessly into functional, sports, and vegan categories. Operationally, they’re logistically efficient easy to store, seasonally predictable, and broadly available across Europe.

Manufacturers are increasingly using kernels as nut alternatives, not only for the macro profile but also for allergen-friendliness and attractive lifecycle attributes compared to several other oilseeds. Their neutral taste, crunch, and broad application range from bakery to high-protein and vegan snacks make them one of the most valuable components of modern food production.

Summary: sunflower kernels embody what today’s food industry values most: naturalness, functionality, durability, and accessibility. In conclusion, these qualities will keep their relevance growing over the coming decades.

Related article: Sunflower Market Update – September 2024

FAQ – Buyers Frequently Asked Questions

Q1: What’s the difference between sunflower seeds and sunflower kernels?

Seeds are whole with shells; kernels are the dehulled, edible parts ready for food production.

Q2: What are the main applications for sunflower kernels?

Bakery (breads, rolls, granola), snacks (roasted/salted/seasoned), ingredients (flour, pastes, sunflower protein), wholesale & packing and industrial food processing.

Q3: How do Bakery Grade and Confectionary Grade differ?

Bakery grade = smaller kernels with a higher share of halves (commonly up to 8%); great for doughs and toppings.

Confectionary grade = lighter in color, larger, more uniform kernels used in roasted snacks and premium consumer products.

Q4: When is the main harvest season in Europe?

In Central and Eastern Europe (Ukraine, Bulgaria, Romania, Hungary). The peak harvest is September–October, when volumes are highest and pricing most competitive.

Practical FAQs About Sunflower Kernel Quality and Use

Q5: How long can sunflower kernels be stored?

In cool, dry conditions (<10% humidity, <15°C), kernels remain stable for 12–18 months.

Q6: Do organic kernels differ substantially from conventional?

Yes. Organic lots come from fields without synthetic fertilizers or pesticides and often have 30–40% lower yields. However they support clean-label positioning and typically carry EU Organic or USDA NOP certification.

Q7: Are sunflower kernels “eco-friendly”?

Not entirely. Processing is near zero-waste and rotations can benefit soil, but intensive cultivation is nutrient-demanding. Sustainable outcomes depend on agronomy: rotations, soil management, and smart nutrient use.

Q8: Why do sunflower kernels matter to manufacturers?

They combine nutrition, year-round availability, and formulation flexibility. Enabling use across multiple categories; from bakery to functional and plant-based foods, while supporting allergen-sensitive product lines.

Source:

- “Physical Properties of Sunflower Seeds“ – https://www.sciencedirect.com/science/article/abs/pii/S0021863496901110?

- “New EU Maximum Levels for Contaminants in Foods: Aflatoxins, Metals, and More” – https://www.food-safety.com/articles/8573-new-eu-maximum-levels-for-contaminants-in-foods-aflatoxins-metals-and-more?

- “Scientific assistance to assess the detoxification process for dioxins and PCBs in sunflower cake by hexane extraction” – https://www.efsa.europa.eu/en/efsajournal/pub/5398?

- “Sunflower seed byproduct and its fractions for food application: An attempt to improve the sustainability of the oil process” – https://ift.onlinelibrary.wiley.com/doi/full/10.1111/1750-3841.15719?

- “Oilseed crop sunflower (Helianthus annuus) as a source of food: Nutritional and health benefits” – https://pmc.ncbi.nlm.nih.gov/articles/PMC7500752/?